|

Septic System History

Back in the “old days”, the standard method of liquid waste disposal was to install a pipe from the house to the closest water body and let it all go downhill. After discovering this method of wastewater disposal pollutes our waterways, causes disease and can be lethal to humans and animals, newer methods were created. To help solve these initial problems, “standard gravity” soil treatment systems were introduced. This type of a system allowed the solids to settle out in a tank and the liquids to be filtered by gravity through the native soil. Putting the liquid waste into the ground instead of straight into our surface water was a good first step, but other problems ensued. Sites with poor draining soils were found to sometimes have a seasonal water table near the surface in the wintertime. Having a drainfield in a “perched” water table would oftentimes cause the system to back up into the house or cause pre-mature failure. On sites with excessively well drained soils (fractured rock, etc), there wasn’t enough filter material (dirt) to adequately treat the effluent before the pollutants made it into the aquifer. This caused contamination of our ground water which was also found to be a problem. Today’s regulators have studied many of these problems previously experienced and changed the septic system regulations to help increase the life of our systems and also try to protect the public from contamination of surface and ground water. The rules are not perfect, but most have been created based on documented problems and some scientific research. |

|

How They Work - General

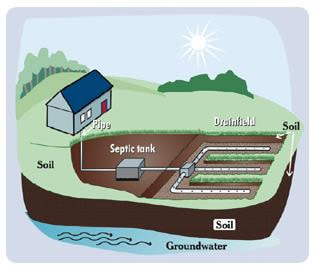

The septic system is a natural method of treating and disposing liquid household waste. The first component of all septic systems is the tank. Most tanks are split into two compartments and have pipe baffles and an outlet filter to ensure the solids stay in the tank. The biologic process begins in the tank where the effluent separates into layers and begins the process of decomposition. Bacteria, which are naturally present in all septic systems, begin to digest the solids that have settled to the bottom of the tank, transforming a large percentage of these solids into liquids and gases. When liquids within the tank rise to the level of the outflow pipe, they enter the next part of the treatment system (pre-treatment device, distribution box, pump chamber, etc, depending on the type of system). Final treatment of the effluent always occurs in the soil where additional microbes break down the waste and the “clean” water is put back into the ground thereby recharging the aquifers. Wastewater contains several undesirable pollutants. Pathogens such as viruses or bacteria can enter drinking water supplies creating a potential health hazard. Nutrients and organic matter entering waterways can lead to tremendous growth in the quantity of aquatic microorganisms. Metabolic activity of these microbes can reduce oxygen levels in the water causing aquatic life to suffocate. Septic system regulations attempt to reduce the chance of these pollutants from having a negative impact on people and animals. Septics 101 Chapter 1: Introduction and Sewage Overview https://www.youtube.com/watch?v=U5-NUYcWXGg&t=4s For lots of technical information from the State of Washington, check out this document: http://www.doh.wa.gov/Portals/1/Documents/Pubs/337-083.pdf NOTE: This is only if you really want to “geek out”. :-) Types of Systems - General There are many, many types and sizes of septic systems available today. In Washington, the systems are divided up into four basic categories:

The first two types (standard gravity and pressure distribution) are relatively straightforward, non-proprietary system types. Standard gravity systems require three feet of "good" soil under the trenches while pressure distribution systems only require two feet. Advanced Treatment systems are more complicated and treat the wastewater to a fairly high level before allowing it to reach the soil. Because of this treatment, they can be used where there is only one foot of "good" dirt beneath the trench bottom. Advanced treatment systems come in many makes, models and sizes. Some are proprietary, name brand systems and others are not. Many systems today include pump(s), control panels, graveless infiltration chambers and effluent filters. Some systems even include textile filters, aerobic digestion and/or ultraviolet disinfection! Video on types of septic systems in WA https://www.youtube.com/watch?v=3ZANsnpx3tg If you want to read more details on the different types of system, continue scrolling. |

|

Standard Gravity

Once we have your design package completed, we’ll submit it for County review. We typically ask for a check from you to pay for the County application fees. We simply submit your check with the design package and the review process begins. This process normally takes 2-4 weeks. We will also prepare a “pdf” copy of the design and send it to you via email. Once we have the approved design back, we typically ask for our invoice to be paid before releasing the approval. |

|

When you send new liquid waste into the septic tank, an equal amount of liquid (called effluent) comes out the outlet side of the tank. An “outlet filter” is installed in the tank to help prevent solids from escaping the tank.

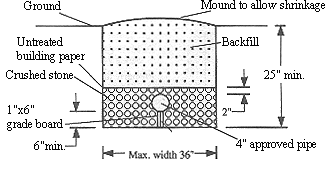

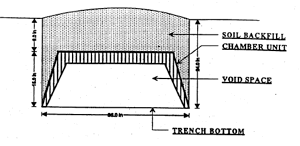

After passing through the outlet filter, the effluent flows through a distribution box (d-box) which diverts the flows to multiple pipes. The effluent leaves the d-box under the power of gravity and flows downhill to each of the underground drainage trenches. The trenches are made up of either: perforated pipe over drainrock or graveless chambers. Each type effectively does the same thing…they allow the effluent to “perc” into the ground at the bottom of the trench. |

|

In Washington State, the bottom of the drainfield trench needs to be 3 feet above any restrictive layer, such as a hardpan, water table or excessively permeable soil (rock) in order to permit a gravity system. Chemical and biological processes treat the effluent as it percolates down through the soil. The size of the drainfield depends on the estimated daily wastewater flow and the soil conditions at your site.

A residential gravity septic system typically costs in the $7,000-$9,500 range to have installed. |

|

Pressure Distribution

Pressure distribution systems are usually required when there is less than optimal soil depth available for complete treatment of the effluent by a gravity system. A minimum of two feet of properly drained soil is required under the trenches. The tank and drainfield size are normally the same as a standard gravity system, but the method by which the effluent is distributed to the soil is different. A pump (or sometimes a siphon) is used to pressurize the effluent into a small underground pvc pipe which transports it to the drainfield. The drainfield itself consists of pipe and rock, graveless chambers or drip irrigation tubing. Unlike a standard gravity system, a pressure distribution system wets the entire length of the trench each time the pump turns on. This allows the effluent to be spread over a larger area and receive better treatment from the soil. A residential pressure distribution system typically costs between $9,000 and $13,000 to have installed. |

|

Advanced Treatment Systems:

Advanced treatment systems come in many makes and varieties. Some are built in a factory and some are built on site. Some are proprietary and some are public domain. These systems are required when shallow soils exist on the site (12-30 inches typically). The basic function of these systems is to clean the wastewater prior to the final disposal into the ground. Most of the time, these treatment systems are followed by pressure distribution drainfields (trenches or drip tube). The most common types of pre-treatment systems found in Clark County include the following:

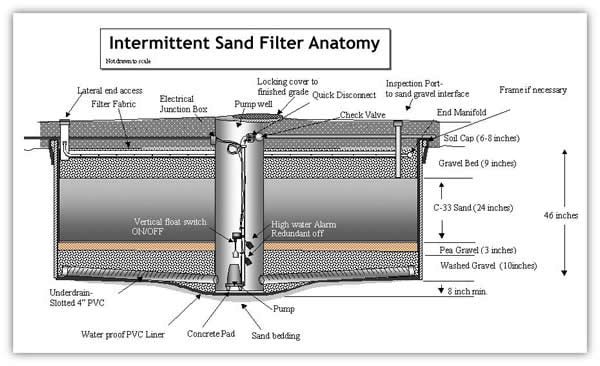

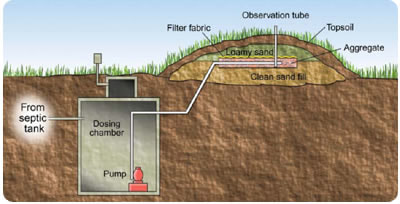

Advanced treatment systems for residential projects typically cost in the $13,000 - $20,000 range. They can be more if larger than typical or in the case of very difficult site constraints. In very rare cases, a residential system could cost upwards of $50,000. This is quite rare however. Sand Filter – After the septic tank, a pump sends pressurized effluent to a large underground box which is full of sand and drainrock. Effluent is spread evenly over the surface of the sand via a pressurized pipe network (similar to a pressure distribution system). The dirty effluent filters through the sand and collects in a sump at the bottom. A second pump sends the relatively clean effluent to the drainfield where the final treatment occurs and the effluent is disposed in the soil. Many sand filters were installed in years past, but new technology has mostly replaced sand filters today. Sand Mounds – Another system suited for sites with shallow soils is a sand mound. A mound is a drainfield raised above the natural soil surface with a sand fill material. Within the sand fill is a network of pressurized pipes similar to a pressure drainfield. Septic tank effluent is pumped through the pipes in controlled doses to insure uniform distribution throughout the bed. Treatment of the effluent occurs as it moves downward through the sand and directly into the natural soil beneath. Sand mounds were used a lot in Clark County in the late 1980’s and through the 1990’s. They are used less often today, and when they are, the design oftentimes allows a shorter height than in the past.

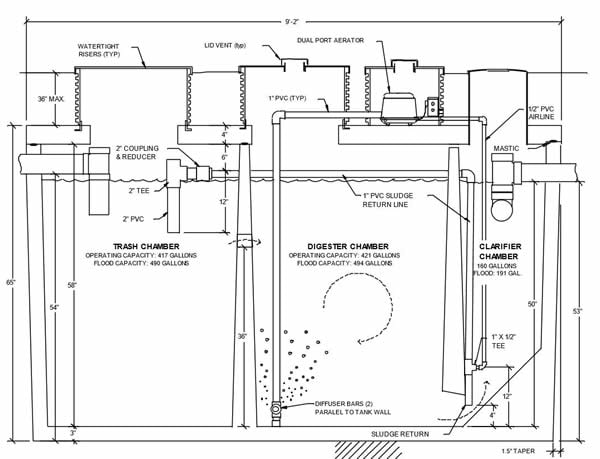

Aerobic Treatment – Another method of treating wastewater involves an “aerobic” process by which air is injected into the effluent in a specific manner. The increased levels of oxygen in the effluent allow the microorganisms to thrive and digest the biological nutrients. A small air compressor is used to inject air into the effluent. The sand filters described above have been mostly replaced with this type of unit. They are less expensive to install, take up less land area and easier to repair if/when needed.

Textile Filter (AdvanTex) – Considered to be one of the higher quality treatment systems available, AdvanTex filters could be considered the “Cadillac” of septic systems. Similar to a sand filter, the AdvanTex filter uses media to filter out the contaminants in the effluent. Instead of sand however, the AdvanTex uses a textile product.

EGSD has designed many AdvanTex systems, but typically now recommends the NuWater aerobic system. The NuWater system is less costly to install and does not require a UV light like the AdvanTex. Glendon® Biofilters – Glendon Bilfilters are used on the really tough sites, typically where seasonal groundwater or significant rock is found at 12-18 inches below the surface. The system consists of different layers of sand and gravel placed in a watertight box built into the soil with a sand fill placed over the top of the entire area. Effluent is pumped into the bottom of the filter and allowed to wick itself up through the sand and over the rim of the box and into the soil (effluent remains under the cover sand). Typically one “pod” is used for each bedroom in the residence (or 120 gal/day of wastewater on a commercial project). In Clark County, we are now typically using an aerobic treatment tank “below ground” and a shallow sand mound instead of Glendon pods due to aesthetics. The Glendon system is still used however, and has advantages to a mound in some circumstances.

|

As a home builder, I've dealt with other septic designers. Mike and Keith are the best...timely, responsive, highly competent technically, and they provide outstanding value.

Chris S.